Tire Testing Services

Tire Testing Services for all Vehicle and Tire Development Needs

Calspan’s testing is performed onsite at our test facility, which is the most premier indoor tire test facility of its kind in the world. It is here that our staff works to deliver unparalleled value to the innovators that rely on our expertise. The facility’s unique combination of speed and torque enables cutting-edge research and robust data quality.

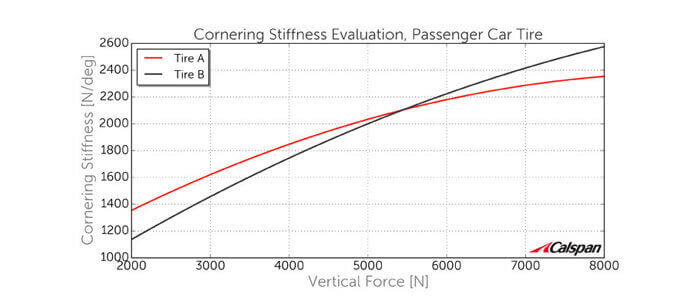

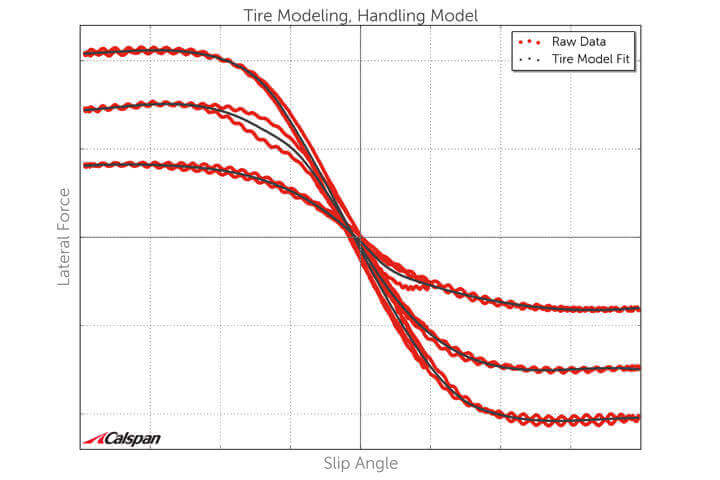

Force & Moment

Force & Moment data provides detailed insight into how tire forces and moments generated in the contact patch influence tire and vehicle handling and stability.

Ride & Durability

Ride & Durability data is used to understand how vehicle travels over uneven surfaces and how road forces are reacted into the vehicle, influence ride comfort and component durability.

Research Studies

Research studies often include using specialized instrumentation to measure and understand specific tire phenomena that may have an impact on your product's strength, performance and cost.

ADVANCED MEASUREMENTS

With over 40 years of experience, Calspan can help innovators with any advanced measurements and executing custom exploratory tests. Our research-grade data acquisition system can easily be configured with additional sensors. In close cooperation with sensor manufacturers, we can develop the measurement equipment needed to collect data to solve almost any problem, including tire wear. Almost no measurement is too difficult or complex; we have a long history of developing custom test setups and procedures to produce the highest quality tire data.

Capabilities:

- Measure complex tire behaviors through integration of additional research-grade sensors to the tire measurements.

- Integrate additional measurements to the main data acquisition or sync measurements to third-party data acquisition.

- Use slip-rings or wireless data transfer to perform on-wheel or in-tire measurements such as temperature or strain.

- Test and evaluate intelligent tire technology performance and durability in a controlled and repeatable environment.

Perform three-dimensional deflection measurements in dynamic conditions to validate tire FEA or enhance full vehicle CFD results.

THERMAL TESTING

Temperature has a significant impact on the performance of any tire. Fully understanding tire thermal properties under various speeds, inclination angles and inflation pressures is important when designing tires and trying to maximize their efficiency on vehicles. Using a variety of different sensors to measure such things as external surface, internal carcass and gas temperatures, Calspan can record the complete thermal state of a tire during any test. Additionally, we can advise on dedicated test procedures that produce high resolution thermal data for use in thermal tire modeling and tire material characterization.

- Quantify thermal response of rubber compounds and their effect on tire grip.

- Take real-time measurement of both internal and external tire temperatures.

- Use a fully integrated FLIR IR camera for detailed tread, sidewall and bead temperature studies.

Collect data to fully parameterize thermal tire models.

DURABILITY TESTING

High performance tires often operate at elevated speeds for long periods of time and Calspan’s exceptional capabilities ensure that the tire can go though the same loads, speeds and conditions as it will see in real life. This makes the machine perfect for evaluating tire performance and durability in fully dynamic conditions. Multiple camera angles and strobe lights are available to study standing wave effects and other dynamics behaviours.

- Perform extended testing at speeds over 200 mph/320 km/h on a flat surface to measure high speed durability and performance.

- A powerful road motor ensures constant speed throughout testing and allows for very rapid speed changes (0.8 g).

- Perform complete force and moment tests at high speeds at realistic operating conditions for motorsports and aircraft tires.

Investigate and measure standing wave effects and other high speed phenomena.

WEAR MEASUREMENTS

Using the full dynamic capabilities of Calspan's tire testing machine makes it possible to measure tire wear characteristics in real-life conditions. We are able to perform highly repeatable tests to identify tire wear rates and wear characteristics.

Capabilities:

- Replicate realistic vehicle maneuvers including brake/drive in a controlled environment to capture high resloution tire wear data.

Measure tread wear effects on F&M characteristics and collect data for tire wear modeling from a single test.

Looking For More Information?